Production

-

Laboratory

Producing oil and gas fields face many challenges to maintain maximum long-term production and smooth operation. Lifting and processing produced fluids often lead to a series of problems that must be overcome to maintain production wells and facilities in good working order and economic operations.

These problem areas include:

• Corrosion of metal parts

• Scale deposits

• Wax/asphaltene depositsChemEOR has in-depth experience and technology to evaluate and develop new novel chemistries to address these issues. Our commitment to continuous research optimizes and produces new break through materials to address production problems that results in optimize field operations, and greater profitability.

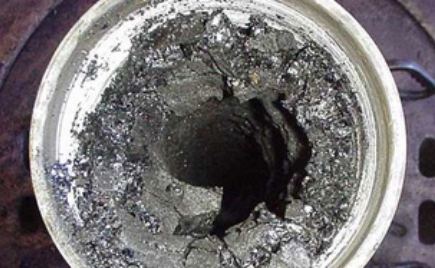

These problems may occur near wellbore, into a well, and into the surface facilities. Any of these operational problems can lead to catastrophic failure of a single well or in key equipment within the surface facilities. Less severe but significant consequences of these phenomena can be:

- • Near wellbore formation damage — reduced well productivity.

- • Repair or replacement required of wellbore hardware such as pump rods and

production tubing, or key equipment in the surface facilities. - • Reduced efficiency and capacity of facility facilities to separate and process

produced oil/gas/water. - • Discharged produced oil/gas fails to meet specifications for export pipeline such

as carryover of excess water; discharged produced water has excess oil and

suspended solids carryover — leading to lost revenue and inefficient water

reinjection or disposal.

We meticulously test our formulations in a vast array techniques with-in our two laboratory facilities with over 15,000 sq. ft. combined space to ensure our chemical solutions meet our customers particular production scenario.

• Electrochemical bubble

• Jet Impingement

• Linear Polarization

• Electrochemical Impedance

Spectroscopy

• Coupon weight loss

• Partition test

• Dynamic tube blocking

• Static bottle

• Capillary suction time (CST)

• Filtration

• Cold Finger

• Solubilization

Product Line

ChemEOR offers production chemicals with superior performance and value to address these particular production problems:

- • Corrosion Inhibitors

- • Scale Inhibitors

- • Wax dissolvers

-

Corrosion Control

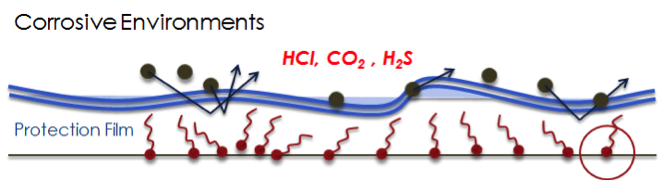

The most common reason for corrosion in oil and gas production systems is the presence of acidic conditions driven by the presence of carbon dioxide (CO2) and hydrogen sulfide (H2S), which are acid gases. Corrosion rates generally will increase with higher acid gas concentrations, pressure, temperature, and brine salinity. Even modest corrosion rates are a concern because that is still a threat to metal materials where ideally the service life is many years without failure.

A different class of corrosion inhibitors addresses the case when concentrated hydrochloric acid solution (15% or more HCl) is used as a stimulation/cleaning treatment for production wells. This can be used, for example, to dissolve and remove bothersome calcium carbonate or other acid-soluble deposits.

Corrosion inhibitors are applied to coat the exposed metals with a protective chemical film in the producing well and the surface facilities so as to minimize corrosion rates. Corrosion inhibitors may be applied downhole or in the surface facility in a continuous fashion or as a batch treatment.

Product Line

CO2/H2S CORROSION INHIBITOR

High performance proprietary inhibitor for upstream and midstream application.

ACID CORROSION INHIBITOR

Environmental friendly inhibitor for acid jobs. -

Scale Control

The term Scale refers to water-borne mineral deposits and suspended solids that precipitate from oilfield waters. The accumulation of such mineral scale deposits downhole can reduce oil production or even block the flow into a production well. These mineral deposits in the surface facilities also can block normal flow or disrupt the efficiency of the separation and processing of produced fluids to meet their specified quality requirements.

Product Line

SCALE INHIBITOR

Specialized additives for inhibition of CaCO3, CaSO4, BaSO4, and silicate scales. -

Wax Control

ChemEOR has developed unique downhole chemical remediation products to remove paraffin and asphaltene deposits. When the formulation is injected into the wellbore on the backside down the annulus, it will dissolve the organic obstruction, which is then carried in the crude oil to a storage tank without re-precipitation. As a result, the formulation will dissolve and disperse the solid deposits/hydrocarbon in the annulus, perforation area, and around the pumps. In addition, the technology has also proven to be effective in removing organic deposits in the transit lines and tanks. This means prevention and removal without re-precipitation.

Product Line

PARAFFIN DISSOLVER

Compounds that enhance reservoir production and remove paraffin deposits, which can clog tubing, reduce flow rates and damage pumping equipment. -

Foam Control

During production, oil and gas are diverted into separate streams for transportation and processing. Defoamers lower interfacial tension and increase the effectiveness of mechanical separators in releasing trapped gases, minimizing the presence of oil in the gas stream and vice versa.

Product Line

DEFOAMERS

Exhibits excellent breaking and inhibiting foam performance.